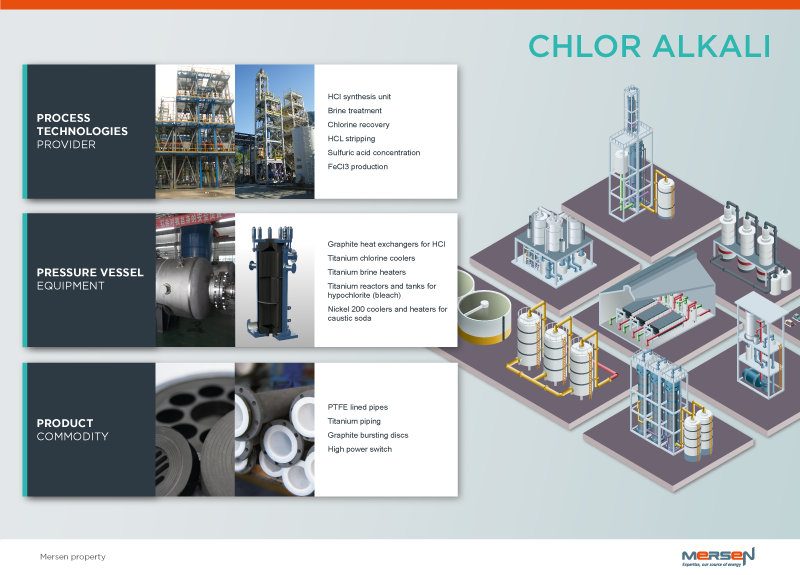

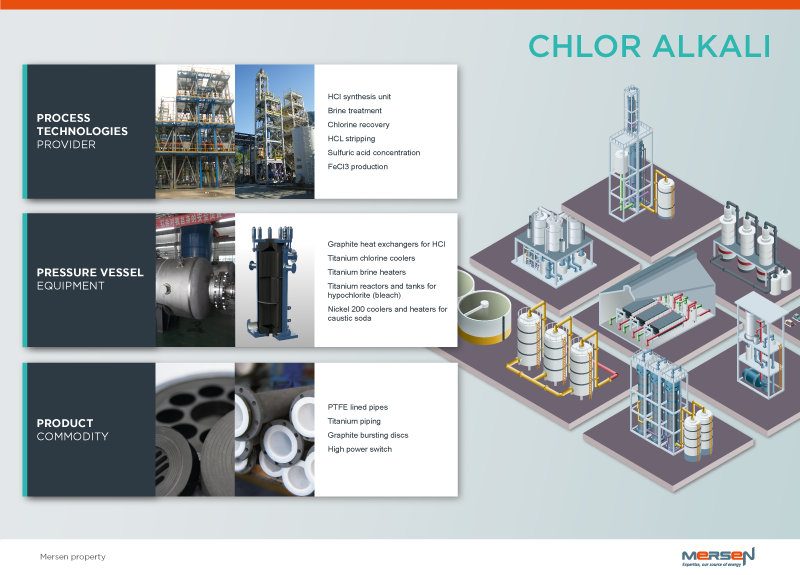

Chlor-alkali

Mersen is a technical member of EUROCHLOR.

Focus on the electrolysis process / HCL Synthesis

The heart of Chlor-Alkali process is the electrolysis of NaCl brine (sodium chloride) or KCl brine (potassium chloride) to produce chlorine (Cl2), caustic soda (NaOH, sodium hydroxide) or caustic potash (KOH, potassium hydroxide) and hydrogen (H2), which are commodity chemicals required by industry.

Mersen has a long-term partnership agreement with APPLITEK (an on-line analyser company) whose objective it to improve the Sintaclor safety and control.

Sintaclor

Production of ultra-pure HCl by synthesis of Cl2 and H2.

Sintaclor is the best solution to obtain ultra-pure HCl (< 1ppm free Cl2)

Mersen has installed more than 600 Cl2 burner units in the world, since 1960, cumulating a yearly production of 9 million t HCl. The leading producers of Cl2 and H2 trust our know-how.

Mersen has enlarged its Cl2 burner portfolio with the third generation called Sintaclor Eco&Flex.

Other process technologies

- Brine debromination technology.

- Spend sulfuric acid concentration coming from Cl2 drying.

- Production of FeCl3 (Ferric chloride) technology from iron scrap.

- Absorption of HCl gas.

- Distillation of HCl liquid to produce HCl gas.

- Production of HCl anhydrous gas.

- Drying of HCl gas.

- Dilution of HCl liquid.

Process equipment

- Nickel 200 vessels for caustic soda.

- Titanium equipment for chlorine condensers.

- Titanium equipment for sodium hypochlorite

Mersen is a global leader combining engineering and supply of equipment for the HCl burner technology, providing the best available design for safety and environment.