Silicon carbide SiC for ground & space telescopes and scientific instrumentation

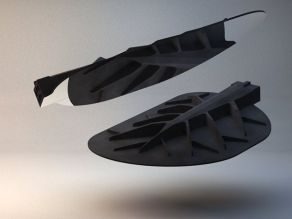

Boostec® SiC provides an ideal solution for instruments requiring exceptional thermomechanical stability. Using Boostec® technology, whole instruments can be made in SiC: structure and detector supports as well as the mirrors themselves.

The optical face of the mirrors can receive a SiC CVD coating to produce a completely non-porous surface, for a flawless polishable finish. Mersen Boostec's know-how also extends to structural bonding and bolting techniques for assembling SiC parts together or with parts made of other materials.